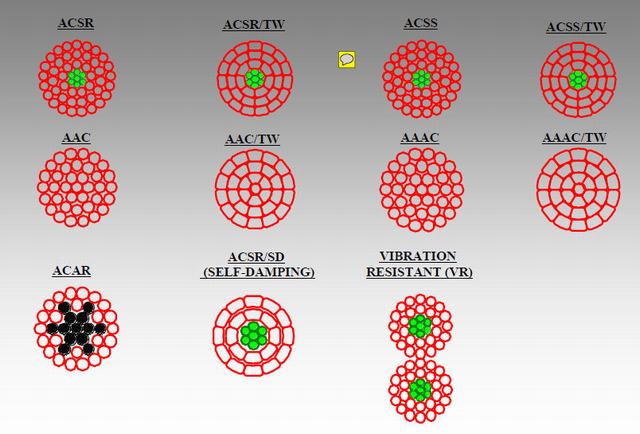

Cavo ACSR/Tw, AAC, AAAC, Acss/Tw, Aacsr, Acar ASTM, IEC Standard

Informazioni di Base

Model No..

Bare Conductor

Tipo

Nudo

Tipo di conduttore

Stranded

Applicazione

Alto

Materiale del conduttore

Alluminio

Materiale di isolamento

Nudo

Forma Materiale

Filo tondo

Certificazione

ISO9001 ,

CE ,

UL ,

CCC

CE ,

UL ,

CCC

Informazioni Aggiuntive.

Marchio

HUATONG

Imballaggio

Drum

Standard

SATM/DIN/IEC

Origine

China

Codice SA

7614900000

Capacità di Produzione

5000km/Month

Descrizione del prodotto

ACSS/TW,annealed Aluminium Conductors Steel Supported (ASTM B 857)

Construction

ACSS/TW, a nonhomogeneous conductor, is a trapezoidal shaped wire compact concentriclay- stranded conductor made from aluminum 1350-O wires and round, coated steel core wire(s). ACSS/TW conductors withequal area or equal diameter as compared to ACSS conductors are available for overhead lines. Steel wires are coated with Class A coating of zinc – 5% aluminum mischmetal alloy. Other Classes of coatings are also available for additional protection from corrosion. Standard, High, Extra and Ultra High Strength steel are also available.

Specifications

ACSS/TW conductors are manufactured in accordance with the ASTM specification B857.

Features

ACSS conductors are preferred over ACSR conductors for specific transmission line

applications:

With zinc – 5% aluminum mischmetal alloy coating on steel wires, ACSS conductors can be operated

up to 250 °C.

ACSS conductors carry more current than ACSR conductors due to:

— Minimum average conductivity of 63% IACS for 1350-O aluminum wires vs. an average conductivity of 61.2% for 1350-H19 aluminum wires in ACSR.

— ACSS conductors can be operated up to 250 °C vs. the maximum operating temperature for an ACSR conductor does not exceed 100 °C.

ACSS conductors are prone to resist the effects of aeolian vibration due to very little or no mechanical load on the annealed aluminum wires.

Long term creep is not a factor when designing with ACSS conductors. In addition, use of ACSS/TW with the equal area design allows equal ampacity in a conductor with approximately 10% smaller diameter over a standard ACSS with same area. This smaller diameter of equal area ACSS/TW conductors helps reduce the effects of ice and wind loading on the conductor.

Alternatively, use of ACSS/TW with equal diameter design provides a conductor in which the aluminum area is increased by approximately 20% – 25% over a standard ACSS with same diameter. This increase

in the cross-sectional area of the conductor reduces its ac resistance by about 15% – 20% and thus, increases its current carrying capacity by about 10%.

Construction

ACSS/TW, a nonhomogeneous conductor, is a trapezoidal shaped wire compact concentriclay- stranded conductor made from aluminum 1350-O wires and round, coated steel core wire(s). ACSS/TW conductors withequal area or equal diameter as compared to ACSS conductors are available for overhead lines. Steel wires are coated with Class A coating of zinc – 5% aluminum mischmetal alloy. Other Classes of coatings are also available for additional protection from corrosion. Standard, High, Extra and Ultra High Strength steel are also available.

Specifications

ACSS/TW conductors are manufactured in accordance with the ASTM specification B857.

Features

ACSS conductors are preferred over ACSR conductors for specific transmission line

applications:

With zinc – 5% aluminum mischmetal alloy coating on steel wires, ACSS conductors can be operated

up to 250 °C.

ACSS conductors carry more current than ACSR conductors due to:

— Minimum average conductivity of 63% IACS for 1350-O aluminum wires vs. an average conductivity of 61.2% for 1350-H19 aluminum wires in ACSR.

— ACSS conductors can be operated up to 250 °C vs. the maximum operating temperature for an ACSR conductor does not exceed 100 °C.

ACSS conductors are prone to resist the effects of aeolian vibration due to very little or no mechanical load on the annealed aluminum wires.

Long term creep is not a factor when designing with ACSS conductors. In addition, use of ACSS/TW with the equal area design allows equal ampacity in a conductor with approximately 10% smaller diameter over a standard ACSS with same area. This smaller diameter of equal area ACSS/TW conductors helps reduce the effects of ice and wind loading on the conductor.

Alternatively, use of ACSS/TW with equal diameter design provides a conductor in which the aluminum area is increased by approximately 20% – 25% over a standard ACSS with same diameter. This increase

in the cross-sectional area of the conductor reduces its ac resistance by about 15% – 20% and thus, increases its current carrying capacity by about 10%.

| Code | Size | Type | Stranding | Nominal Overall Diameter | Cross Section | |||||

| Aluminum | Steel | |||||||||

| AWG or kcmil | No. Al Wires | No. Al Layers | No. of Wires | Diameter | CDR | Steel Core | Al | Total | ||

| in | in | in2 | ||||||||

| Flicker/ACSS/TW | 477.0 | 13 | 18 | 2 | 7 | 0.0940 | 0.78 | 0.2820 | 0.3748 | 0.4234 |

| Hawk/ACSS/TW | 477.0 | 16 | 18 | 2 | 7 | 0.1053 | 0.79 | 0.3159 | 0.3745 | 0.4355 |

| Parakeet/ACSS/TW | 556.5 | 13 | 18 | 2 | 7 | 0.1015 | 0.84 | 0.3045 | 0.4372 | 0.4938 |

| Dove/ACSS/TW | 556.5 | 16 | 20 | 2 | 7 | 0.1138 | 0.85 | 0.3414 | 0.4371 | 0.5083 |

| Rook/ACSS/TW | 636.0 | 13 | 18 | 2 | 7 | 0.1085 | 0.89 | 0.3255 | 0.4994 | 0.5641 |

| Grosbeak/ACSS/TW | 636.0 | 16 | 20 | 2 | 7 | 0.1216 | 0.91 | 0.3648 | 0.4996 | 0.5809 |

| Tern/ACSS/TW | 795.0 | 7 | 17 | 2 | 7 | 0.0888 | 0.96 | 0.2664 | 0.6247 | 0.6680 |

| Puffin/ACSS/TW | 795.0 | 11 | 21 | 2 | 7 | 0.1108 | 0.98 | 0.3324 | 0.6241 | 0.6916 |

| Condor/ACSS/TW | 795.0 | 13 | 21 | 2 | 7 | 0.1213 | 0.99 | 0.3639 | 0.6242 | 0.7051 |

| Drake/ACSS/TW | 795.0 | 16 | 20 | 2 | 7 | 0.1360 | 1.01 | 0.4080 | 0.6242 | 0.7259 |

| Phoenix/ACSS/TW | 954.0 | 5 | 30 | 3 | 7 | 0.0837 | 1.04 | 0.2511 | 0.7497 | 0.7882 |

| Rail/ACSS/TW | 954.0 | 7 | 32 | 3 | 7 | 0.0971 | 1.06 | 0.2913 | 0.7493 | 0.8011 |

| Cardinal/ACSS/TW | 954.0 | 13 | 21 | 2 | 7 | 0.1329 | 1.08 | 0.3987 | 0.7492 | 0.8463 |

| Snowbird/ACSS/TW | 1033.5 | 5 | 30 | 3 | 7 | 0.0871 | 1.09 | 0.2613 | 0.8115 | 0.8532 |

| Ortolan/ACSS/TW | 1033.5 | 7 | 33 | 3 | 7 | 0.1010 | 1.10 | 0.3030 | 0.8112 | 0.8673 |

| Curlew/ACSS/TW | 1033.5 | 13 | 21 | 2 | 7 | 0.1383 | 1.13 | 0.4149 | 0.8118 | 0.9170 |

| Avocet/ACSS/TW | 1113.0 | 5 | 30 | 3 | 7 | 0.0904 | 1.13 | 0.2712 | 0.8737 | 0.9186 |

| Bluejay/ACSS/TW | 1113.0 | 7 | 33 | 3 | 7 | 0.1049 | 1.14 | 0.3147 | 0.8746 | 0.9351 |

| Finch/ACSS/TW | 1113.0 | 13 | 39 | 3 | 19 | 0.0862 | 1.18 | 0.4310 | 0.8737 | 0.9845 |

| Oxbird/ACSS/TW | 1192.5 | 5 | 30 | 3 | 7 | 0.0936 | 1.17 | 0.2808 | 0.9361 | 0.9843 |

| Bunting/ACSS/TW | 1192.5 | 7 | 33 | 3 | 7 | 0.1086 | 1.18 | 0.3258 | 0.9368 | 1.0016 |

| Grackle/ACSS/TW | 1192.5 | 13 | 39 | 3 | 19 | 0.0892 | 1.22 | 0.4460 | 0.9369 | 1.0556 |

| Scissortail/ACSS/TW | 1272.0 | 5 | 30 | 3 | 7 | 0.0967 | 1.20 | 0.2901 | 0.9994 | 1.0508 |

| Bittern/ACSS/TW | 1272.0 | 7 | 33 | 3 | 7 | 0.1121 | 1.22 | 0.3363 | 0.9994 | 1.0685 |

| Pheasant/ACSS/TW | 1272.0 | 13 | 39 | 3 | 19 | 0.0921 | 1.26 | 0.4605 | 0.9987 | 1.1252 |

| Dipper/ACSS/TW | 1351.5 | 7 | 33 | 3 | 7 | 0.1155 | 1.25 | 0.3465 | 1.0616 | 1.1350 |

| Martin/ACSS/TW | 1351.5 | 13 | 39 | 3 | 19 | 0.0949 | 1.30 | 0.4745 | 1.0610 | 1.1954 |

| Bobolink/ACSS/TW | 1431.0 | 7 | 33 | 3 | 7 | 0.1189 | 1.29 | 0.3567 | 1.1243 | 1.2020 |

| Plover/ACSS/TW | 1431.0 | 13 | 39 | 3 | 19 | 0.0977 | 1.33 | 0.4885 | 1.1242 | 1.2666 |

| Lapwing/ACSS/TW | 1590.0 | 7 | 36 | 3 | 7 | 0.1253 | 1.36 | 0.3759 | 1.2488 | 1.3351 |

| Falcon/ACSS/TW | 1590.0 | 13 | 39 | 3 | 19 | 0.1030 | 1.40 | 0.5150 | 1.2483 | 1.4066 |

| Chukar/ACSS/TW | 1780.0 | 8 | 38 | 3 | 19 | 0.0874 | 1.45 | 0.4370 | 1.3982 | 1.5122 |

| Bluebird/ACSS/TW* | 2156.0 | 8 | 64 | 4 | 19 | 0.0961 | 1.61 | 0.4805 | 1.6934 | 1.8312 |

| Mohawk/ACSS/TW | 571.7 | 13 | 18 | 2 | 7 | 0.103 | 0.846 | 0.309 | 0.4489 | 0.5072 |

| Calumet/ACSS/TW | 565.3 | 16 | 20 | 2 | 7 | 0.1146 | 0.858 | 0.3438 | 0.4438 | 0.5161 |

| Mystic/ACSS/TW | 666.6 | 13 | 20 | 2 | 7 | 0.1111 | 0.913 | 0.3333 | 0.5236 | 0.5915 |

| Oswego/ACSS/TW | 664.8 | 16 | 20 | 2 | 7 | 0.1244 | 0.927 | 0.3732 | 0.5222 | 0.6073 |

| Maumee/ACSS/TW | 768.2 | 13 | 20 | 2 | 7 | 0.1195 | 0.977 | 0.3585 | 0.6032 | 0.6817 |

| Wabash/ACSS/TW | 762.8 | 16 | 20 | 2 | 7 | 0.1331 | 0.99 | 0.3993 | 0.5989 | 0.6963 |

| Kettle/ACSS/TW | 957.2 | 7 | 32 | 3 | 7 | 0.0973 | 1.06 | 0.2919 | 0.7518 | 0.8038 |

| Suwannee/ACSS/TW | 959.6 | 16 | 22 | 2 | 7 | 0.1493 | 1.108 | 0.4479 | 0.7539 | 0.8764 |

| Cheyenne/ACSS/TW | 1168.1 | 5 | 30 | 3 | 7 | 0.0926 | 1.155 | 0.2778 | 0.917 | 0.9642 |

| Genesee/ACSS/TW | 1158.0 | 7 | 33 | 3 | 7 | 0.1078 | 1.165 | 0.3234 | 0.9094 | 0.9732 |

| Hudson/ACSS/TW | 1158.4 | 13 | 26 | 2 | 7 | 0.1467 | 1.196 | 0.4401 | 0.9096 | 1.0279 |

| Catawba/ACSS/TW | 1272.0 | 5 | 30 | 3 | 7 | 0.0967 | 1.203 | 0.2901 | 0.9993 | 1.0507 |

| Nelson/ACSS/TW | 1257.1 | 7 | 35 | 3 | 7 | 0.1115 | 1.213 | 0.3345 | 0.9875 | 1.0558 |

| Yukon/ACSS/TW | 1233.6 | 13 | 38 | 3 | 19 | 0.091 | 1.25 | 0.455 | 0.9685 | 1.0921 |

| Truckee/ACSS/TW | 1372.5 | 5 | 30 | 3 | 7 | 0.1004 | 1.248 | 0.3012 | 1.0783 | 1.1337 |

| Mackenzie/ACSS/TW | 1359.7 | 7 | 36 | 3 | 7 | 0.1159 | 1.259 | 0.3477 | 1.0674 | 1.1413 |

| Thames/ACSS/TW | 1334.6 | 13 | 39 | 3 | 19 | 0.0944 | 1.29 | 0.472 | 1.0479 | 1.1808 |

| St.Croix/ACSS/TW | 1467.8 | 5 | 30 | 3 | 7 | 0.1041 | 1.292 | 0.3123 | 1.1532 | 1.2127 |

| Miramichi/ACSS/TW | 1455.3 | 7 | 36 | 3 | 7 | 0.12 | 1.299 | 0.36 | 1.1427 | 1.2219 |

| Merrimack/ACSS/TW | 1433.6 | 13 | 39 | 3 | 19 | 0.0978 | 1.34 | 0.489 | 1.1255 | 1.2682 |

| Platte/ACSS/TW | 1569.0 | 5 | 33 | 3 | 7 | 0.1074 | 1.334 | 0.3222 | 1.2328 | 1.2962 |

| Potomac/ACSS/TW | 1557.4 | 7 | 36 | 3 | 7 | 0.1241 | 1.345 | 0.3723 | 1.2237 | 1.3084 |

| Rio Grande/ACSS/TW | 1533.3 | 13 | 39 | 3 | 19 | 0.1012 | 1.379 | 0.506 | 1.2046 | 1.3574 |

| Schuylkill/ACSS/TW | 1657.4 | 7 | 36 | 3 | 7 | 0.128 | 1.386 | 0.384 | 1.3012 | 1.3912 |

| Pecos/ACSS/TW | 1622.0 | 13 | 39 | 3 | 19 | 0.1064 | 1.424 | 0.532 | 1.2736 | 1.4425 |

| Pee Dee/ACSS/TW | 1758.6 | 7 | 37 | 3 | 7 | 0.1319 | 1.431 | 0.3957 | 1.3811 | 1.4768 |

| James/ACSS/TW | 1730.6 | 13 | 39 | 3 | 19 | 0.1075 | 1.47 | 0.5375 | 1.3598 | 1.5322 |

| Athabaska/ACSS/TW | 1949.6 | 7 | 42 | 3 | 7 | 0.1392 | 1.504 | 0.4176 | 1.5318 | 1.6384 |

| Cumberland/ACSS/TW | 1926.9 | 13 | 42 | 3 | 19 | 0.1133 | 1.545 | 0.5665 | 1.5129 | 1.7044 |

| Santee/ACSS/TW* | 2627.3 | 8 | 64 | 4 | 19 | 0.1062 | 1.762 | 0.531 | ||

- Next: PVC Insulated Solid Copper Conductor Single Core Electric Wire Cable (BV)

- Previous: Aluminium Clad Steel, Copper Clad Steel Overhead Conductor