R2V Industrial Power Cable per il Togo

Prodotto in dettaglio

Informazioni di Base

Informazioni Aggiuntive.

Descrizione del prodotto

U-1000 R2V

R2V Industrial Power Cable for Togo

Application and Description

These cables for energy distribution are suitable for all types of low voltage industrial-type connection, in urban grids, building installations, etc. Particularly suited in cases of high operating temperature and when high resistance to solar radiation and atmospheric agents is required. Good resistance to low temperature and chemical agents. Can be used without additional mechanical protection in the open air, fixed to walls or in raceways, inside walkways, and in empty in Cable Constructions in general. Can be laid underground with mechanical protection constructed from slabs, tiles, or bricks. They are not recommend to lay this cable in ground flooded for more than two months per year. With appropriate mechanical protection it can be use in areas subject to risk of explosion, but in this case the permitted current load is reduced by 15%. It can be used in ambient temperature down to -25°.

Standard and Approval

NF C 32-321 , EN 60332-1/NF C 32-070

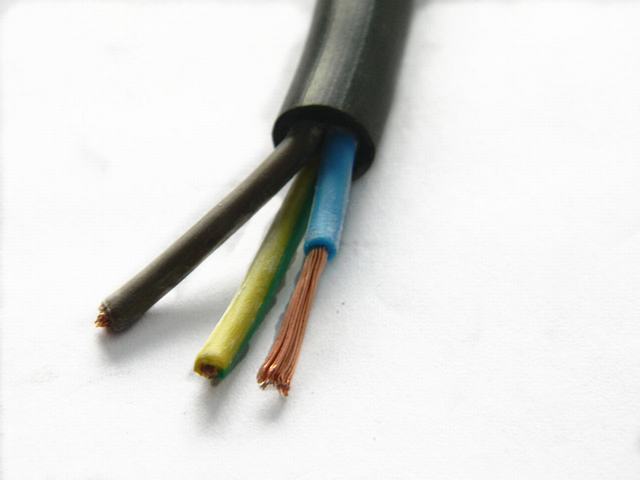

Cable Construction

– Flexible electrolytic annealed copper strands

– Strands to IEC 60228 class 2 , make-up with fine wires (Φ max. 0.4mm) with flexibility level equivalent to class 5.

– XLPE insulation according to NF C 32-321.

– Color codes to NF C32-321

– Not fibrous and not hygroscopic filler

– Flexible black PVC outer jacket

Technical Characteristics

– Working Voltage: 600/1000 volts

– Test voltage: 1200 volts

– Minimum bending radius: 6 x Ø

– Operation temperature range: -15 °C to 60 °C

– Short-circuit temperature: 250 °C

– Flame retardant: NF C 32-070 C2

– Insulation resistance: 20 MΩ x km

Cable Parameter

|

AWG |

Cross Section mm2 |

Insulation thickness mm |

Minimum |

Maximum |

Approx |

|

16 |

1×1.5 |

0.7 |

1.09 |

6.6 |

45 |

|

14 |

1×2.5 |

0.7 |

1.09 |

7 |

55 |

|

12 |

1×4 |

0.7 |

1.09 |

7.6 |

75 |

|

10 |

1×6 |

0.7 |

1.09 |

8.2 |

100 |

|

8 |

1×10 |

0.7 |

1.09 |

9.2 |

140 |

|

6 |

1×16 |

0.7 |

1.09 |

10.5 |

205 |

|

4 |

1×25 |

0.9 |

1.09 |

12.5 |

315 |

|

2 |

1×35 |

0.9 |

1.09 |

13.5 |

400 |

|

1 |

1×50 |

1 |

1.09 |

15 |

530 |

|

2/0 |

1×70 |

1.1 |

1.09 |

17 |

725 |

|

3/0 |

1×95 |

1.1 |

1.18 |

19 |

985 |

|

4/0 |

1×120 |

1.2 |

1.18 |

21 |

1260 |

|

300MCM |

1×150 |

1.4 |

1.26 |

23 |

1520 |

|

500MCM |

1×185 |

1.6 |

1.26 |

25.5 |

1940 |

|

750MCM |

1×240 |

1.7 |

1.35 |

28.5 |

2310 |

|

|

1×300 |

1.8 |

1.43 |

31 |

3200 |

|

16 |

2×1.5 |

0.7 |

1.43 |

10.5 |

115 |

|

14 |

2×2.5 |

0.7 |

1.43 |

11.5 |

145 |

|

12 |

2×4 |

0.7 |

1.43 |

13 |

195 |

|

10 |

2×6 |

0.7 |

1.43 |

14 |

265 |

|

8 |

2×10 |

0.7 |

1.43 |

16 |

390 |

|

6 |

2×16 |

0.7 |

1.43 |

18.5 |

560 |

|

4 |

2×25 |

0.9 |

1.43 |

22 |

850 |

|

2 |

2×35 |

0.9 |

1.43 |

24.5 |

1080 |

|

16 |

3×1.5 |

0.7 |

1.43 |

11 |

130 |

|

14 |

3×2.5 |

0.7 |

1.43 |

12.5 |

170 |

|

12 |

3×4 |

0.7 |

1.43 |

13.5 |

230 |

|

10 |

3×6 |

0.7 |

1.43 |

15 |

325 |

|

8 |

3×10 |

0.7 |

1.43 |

17 |

485 |

|

6 |

3×16 |

0.7 |

1.43 |

19.5 |

705 |

|

4 |

3×25 |

0.9 |

1.43 |

23.5 |

1080 |

|

2 |

3×35 |

0.9 |

1.43 |

26 |

1390 |

|

1 |

3×50 |

1 |

1.43 |

29 |

1840 |

|

2/0 |

3×70 |

1.1 |

1.52 |

34 |

2540 |

|

3/0 |

3×95 |

1.1 |

1.6 |

38.5 |

3430 |

|

4/0 |

3×120 |

1.2 |

1.69 |

42.5 |

4440 |

|

300MCM |

3×150 |

1.4 |

1.86 |

47.5 |

5380 |

|

500MCM |

3×185 |

1.6 |

1.94 |

53 |

6920 |

|

750MCM |

3×240 |

1.7 |

2.11 |

59.5 |

8420 |

|

– |

3×300 |

1.8 |

2.28 |

66 |

11300 |

|

16 |

4×1.5 |

0.7 |

1.8 |

11.3 |

180 |

|

14 |

4×2.5 |

0.7 |

1.8 |

12.2 |

220 |

|

12 |

4×4 |

0.7 |

1.8 |

13.3 |

300 |

|

10 |

4×6 |

0.7 |

1.8 |

15 |

420 |

|

8 |

4×10 |

0.7 |

1.8 |

17.25 |

630 |

|

6 |

4×16 |

0.7 |

1.8 |

18.8 |

900 |

|

4 |

4×25 |

0.9 |

1.8 |

23 |

1350 |

|

2 |

4×35 |

0.9 |

1.8 |

25.1 |

1750 |

|

1 |

4×50 |

1 |

1.9 |

29.1 |

2350 |

|

2/0 |

4×70 |

1.1 |

2 |

33.9 |

3400 |

|

3/0 |

4×95 |

1.1 |

2.1 |

38.4 |

4500 |

|

4/0 |

4×120 |

1.2 |

2.3 |

42.4 |

5700 |

|

300MCM |

4×150 |

1.4 |

2.4 |

47.2 |

7050 |

|

500MCM |

4×185 |

1.6 |

2.6 |

52.65 |

8700 |

|

750MCM |

4×240 |

1.7 |

2.8 |

59 |

11400 |

|

– |

4×300 |

1.8 |

3 |

64.8 |

14200 |

|

1 |

3×50+35 |

1 |

1.8 |

28.8 |

2200 |

|

2/0 |

3×70+50 |

1.1 |

2 |

33.4 |

3100 |

|

3/0 |

3×95+50 |

1.1 |

2.1 |

37 |

3950 |

|

4/0 |

3×120+70 |

1.2 |

2.2 |

41.3 |

5050 |

|

300MCM |

3×150+70 |

1.4 |

2.3 |

45.1 |

6100 |

|

500MCM |

3×185+70 |

1.6 |

2.5 |

50 |

7400 |

|

750MCM |

3×240+95 |

1.7 |

2.7 |

55.8 |

9700 |

|

16 |

5×1.5 |

0.7 |

1.8 |

12.1 |

205 |

|

14 |

5×2.5 |

0.7 |

1.8 |

13.1 |

260 |

|

12 |

5×4 |

0.7 |

1.8 |

14 |

350 |

|

10 |

5×6 |

0.7 |

1.8 |

16.3 |

500 |

|

8 |

5×10 |

0.7 |

1.8 |

18.5 |

760 |

|

6 |

5×16 |

0.7 |

1.8 |

20.6 |

1100 |

|

4 |

5×25 |

0.9 |

1.8 |

25.4 |

1600 |

|

16 |

7×1.5 |

0.7 |

1.8 |

12.3 |

260 |

|

14 |

7×2.5 |

0.7 |

1.8 |

13.2 |

330 |

|

12 |

7×4 |

0.7 |

1.8 |

15.4 |

450 |

|

16 |

8×1.5 |

0.7 |

1.8 |

13.9 |

290 |

|

14 |

8×2.5 |

0.7 |

1.8 |

14.9 |

380 |

|

12 |

8×4 |

0.7 |

1.8 |

16.5 |

520 |

|

16 |

10×1.5 |

0.7 |

1.8 |

15.8 |

350 |

|

14 |

10×2.5 |

0.7 |

1.8 |

17 |

450 |

|

12 |

10×4 |

0.7 |

1.8 |

19 |

630 |

|

16 |

12×1.5 |

0.7 |

1.8 |

15.5 |

390 |

|

14 |

12×2.5 |

0.7 |

1.8 |

16.8 |

510 |

|

12 |

12×4 |

0.7 |

1.8 |

19.6 |

700 |

|

16 |

14×1.5 |

0.7 |

1.8 |

17 |

440 |

|

14 |

14×2.5 |

0.7 |

1.8 |

18.3 |

580 |

|

12 |

14×4 |

0.7 |

1.8 |

20.5 |

800 |

|

16 |

19×1.5 |

0.7 |

1.8 |

17.9 |

550 |

|

14 |

19×2.5 |

0.7 |

1.8 |

19.4 |

740 |

|

12 |

19×4 |

0.7 |

1.8 |

22.6 |

1050 |

|

16 |

24×1.5 |

0.7 |

1.8 |

20.7 |

670 |

|

14 |

24×2.5 |

0.7 |

1.8 |

23.2 |

900 |

|

16 |

30×1.5 |

0.7 |

1.8 |

22.6 |

800 |

|

14 |

30×2.5 |

0.7 |

1.8 |

24.5 |

1100 |

|

16 |

37×1.5 |

0.7 |

1.8 |

23.5 |

950 |

|

14 |

37×2.5 |

0.7 |

1.8 |

26.3 |

1300 |

- Next: Armored Cable Low Voltage (LV) PVC/XLPE Insulated Armoured

- Previous: Welding Cable Flexible Copper Rubber Insulated Wear/Oil/Chemical Resistant 150mm2

Contact us

Simile o correlato

- No related articles